The content in this guide was originally created by Leon @SpikerEng on TacomaWorld as a series of posts over several months. I've captured it here for two reasons:

- I want to make sure that, should anything happen to Leon's post, that we all still have access to this amazingly useful information.

- As happens in forums, the information Leon posted (over time) is interspersed with a bunch of commentary from others. By consolidating it here, it becomes easier to read.

Note: I've slightly edited certain bits of content in order to make the "flow" easier to consume as a single post rather than a series; I've tried not to change any of the meaning in the process.

You can jump to the results if you must, but seriously, this stuff is important - why not read through?

Looking for how to replace your LBJs? Here's how, with pictures: Step-by-Step Replacing Lower Ball Joints (LBJ) on a 1st Gen Tacoma (or 3rd Gen 4Runner)

Everything You Ever Wanted to Know About Lower Ball Joint (LBJ) Bolts

Are aftermarket bolts better than OEM? How much torque should be applied during installation? Can LBJ bolts be reused safely? Should Loctite be used on the bolts?

These questions are important because LBJ bolts have been known to fail from too much preload (which can lead to bolt yielding or breakage), or too little preload (which can lead to bolt loosening or ball joint gapping at the knuckle). All of which means that the wrong bolt type, or the wrong applied torque, can cause the LBJ connection to break, leading to something like this:

Oops.

Adding to confusion about LBJ bolts is the fact that several bolt options are often available from Toyota, and different torque values are specified in factory service manuals for different model years. Some attempts have been made in the past to clear things up in forums over the years but as often happens, these posts often become debates and contain more speculation and opinion than supporting data. Until now.

Here, we’ll bust (or confirm) some common myths about LBJ bolts, such as:

- Myth 1 - Some Toyota LBJ bolts have lower strength than others

- Myth 2 - Some Toyota LBJ bolts have lower friction than others, and require a lower installation torque

- Myth 3 - LBJ bolts yield during installation and are safe for one-time use only

- Myth 4 - Aftermarket bolts are better than OEM Toyota bolts

- Myth 5 - Lower installation torque should be applied when using Loctite

We test five different bolts, both OEM and aftermarket. Although commonly used for the 3rd Gen Toyota 4Runner, these bolts are also used for Tacoma and Sequoia trucks, so the results are applicable across various platforms:

The contestants.

“GREEN” - Toyota 90080-10066 (replaces 90105-10406); Flanged Head Bolt. This bolt is specified for the 1996-2000 4Runner. It’s a flanged head bolt, with “two dot two hash” head marking, which Toyota classifies as Class 11T bolt.

“RED” - Toyota 90105-10505; Flanged Head Bolt; This bolt is specified for the 2001-2002 4Runner, at locations without the protector boot. It is identical in appearance to the Green bolt, with the same Class 11T head markings. However, the red color code suggests that there is a difference between this bolt and the green bolt.

“BLACK” - Toyota 90119-10933; Bolt with Washer. This bolt is specified for the 2001-2002 4Runner, at locations with the protector boot. It is longer than the other bolts, to accommodate the extra thickness of the protector boot. The “11” head markings also classify it as a Class 11T bolt. The captive washer makes this bolt quite different from the flanged heads of all the other bolts.

“ZINC” - This is a Class 10.9 Yellow Zinc plated bolt, often used as a replacement for OEM Toyota bolts. It’s also a flanged head bolt. Purchased from Belmetric, BF10X1.25X30YLW.

“ARP” - This bolt is made by Automotive Racing Products, Part Number 663-1003. It’s an 8740 Chrome Moly steel bolt, with a flanged head, and supplied with an optional washer.

Preload vs. Torque Tests

Our first set of tests characterizes the torque vs. preload relationship for each bolt. Why is this important? Let’s start with the purpose of torquing a bolt - it is to introduce enough clamping load (preload) into the bolt to keep the two bolted parts properly compressed during use. Too much preload, and the bolt may yield or break; too little preload, and the bolt may loosen or allow gapping in the joint.

Ideally, structural analysis would tell us how much preload is needed at each bolt location. With that information, we would measure the actual preload as the bolt is tightened until the desired value is reached. However, this is not practical without special instrumentation, so in most cases we rely on specifying the installation torque, and relating that indirectly to the bolt preload.

When it comes to the LBJ bolts, Toyota specifies different torque values for the ’96-00 models (59 ft-lbs) and ’01-02 models (37 ft-lbs). Since the ball joints and knuckles are identical for all model years, we have to assume that different torque is specified because either:

- Toyota decided in 2001 that less preload is needed than they originally thought, or

- Toyota determined that the ’01-02 bolts achieve the same preload with a lower torque value than the ’96-00 bolts.

Given that the ’96-00 bolts are flanged, and the ’01-02 bolts are hex bolts with washers, the latter is a plausible argument (flanged bolts may have more friction losses under the head). But there is only one to find out, and that is the purpose of this series of tests.

Toyota Factory Service Manual (FSM) torque specs for LBJ bolts.

To measure the torque vs. preload relationship, each bolt is inserted through a 1/4″ thick stainless steel bar (to provide a contact surface under the bolt head similar to the LBJ flange), then through a 10K lbs load cell, and threaded into a 7/16″ thick stainless steel bar, drilled and tapped for 10×1.25 threads. The load cell is connected to a digital multi meter to provide a direct indication of the load in the bolt. The bolts are torqued with a torque wrench, equipped with a torque transducer to accurately read out the applied torque. With this method, we can simultaneously measure the applied torque and the resulting preload in the bolt.

We torque each bolt to 20, 37 and 59 ft-lbs, and measure the load at each torque level. This process is repeated for three bolts of each type to account for unit to unit variability, and the results are then averaged to obtain the best fit torque to preload relationship for the bolt. We then repeat the process three times for each bolt, to measure how much preload at installation torque degrades due to reuse.

Torque vs preload for a brand new bolt of each type. This plot shows the average preload value generated by the three bolts for a given torque, on the first installation.

One thing jumps out right away - the Black bolt (aka “Bolt with Washer”, 90119-10933), generates alotmore preload at any torque value than all the other bolts. At 59 ft-lbs, it would generate around 15,000 lbs, which is higher than the safe limit for these bolts (we drew a red dashed line at 12,000 lbs as the upper limit for now, but we will confirm this later, during the destructive tests).

This chart also explains why Toyota specified a torque of 37 ft-lbs for the Black bolts, as opposed to 59 ft-lbs for the others - it’s not that the bolt is weaker, as some have speculated, but that it reaches the same preload (or higher) at 37 ft-lbs as other bolts do at 59 ft-lbs. So, conclusion number 1 - if you use the Black bolt, do NOT torque it to 59 ft-lbs, you will yield the bolt. Torque it 37 ft-lbs, as specified by Toyota.

The variation between all the other bolts is smaller, but still significant. The Zinc plated 10.9 bolt has about 10% more preload at 59 ft-lbs than the updated OEM LBJ Red bolt (90105-10505). The original OEM LBJ Green bolt (90080-10066) generates only 75% of the preload that the Zinc bolt does.

Using our spreadsheet for estimating torque to preload ratio as a function of bolt geometry and friction coefficient, the data above suggests that the friction coefficient is about 0.15 to 0.2 for all the bolts except Black; the Black bolt friction coefficient is likely below 0.1. That puts it squarely into dry film coating territory, which is pretty sophisticated for an automotive bolt application.

We tried to reverse engineer Toyota’s design intent, although of course these are just assumptions. The original Green bolt generates about 7,300 lbs at the specified 59 ft-lbs torque, while the updated Red bolt generates closer to 8,700 lbs. So we’re assuming that Toyota thought the 7,300 lb preload was a bit low, and in 2001 changed to the Red bolt with a different coating material, to bump the preload up to over 8,000 lbs. That is also consistent with the Black bolt, which generates over 9,000 lbs at its specified torque of 37 ft-lbs. So from this, we took the liberty to assume that the lower safe limit for these installations is around 5,000 lbs (it may be closer to 6,000 or 7,000 lbs for all we know). That lower is represented by the lower dashed red line in the chart.

Preload Degradation with Reuse

It is often speculated on the forums that the LBJ bolts should only be used once, sometimes with the argument that the bolts yield during installation and thus should not be reused. Our data refutes that suggestion - 7,300 to 8,700 lbs at 59 ft-lbs for the flanged OEM bolts, and 9,500 lbs at 37 ft-lbs for the Black bolt is nowhere near the yield point. So from that standpoint, the bolts can be safely reused, unless you torque the Black bolt to 59 ft-lbs, which is guaranteed to yield it.

Note: Just because the bolts are not torqued to yield does not mean that they should be reused! Keep reading...

The other concern with reusing a bolt is the reduction in preload with repeated cycles, due to wear. The chart below shows the percent reduction in preload as a function of repeated cycles, starting with a brand new bolt, and torquing it four times:

Three of the bolts (Black, Zinc, and ARP) maintain above 90% of original preload after the first cycle. Interesting to note that the two OEM flanged bolts (Red and Green) do not, they drop below 90% and 80%, respectively. By the fourth installation, the Green bolt has only half the preload of the first installation. The Black and ARP bolts still maintain 80% of original preload even after four installations.

The wide flange of the flange bolts (left photo) degrades significantly with installation cycles (new on left, four cycles on right). Compare that to the wear on the Black bolt (right photo), which is almost imperceptible. The low wear on the Black bolt also supports the conclusion that it has a dry film coating applied.

Rather than look at percentages, it is more useful to look at actual preload values on each re-use of the bolt over four cycles of torquing to 59 ft-lbs. (Note: The Black bolt line is only for reference, as we should not torque it to 59 ft-lbs; the dashed black line at 37 ft-lbs is a better representation.) We can see the effect of repeated installations on preload is dramatic - in the worst example, the Green bolt drops to our assumed lower safe limit of 5,000 lbs with just one reuse. Additional cycles get the bolt to only about 4,000 lbs of preload.

Torquing and Preload Takeaways

TL;DR - Any of the bolts tested, when torqued to spec, will generate the needed preload on the first installation cycle without torque-to-yield-damage to the bolt. However, only the Black, ARP, or Zinc bolts will generate enough preload on subsequent installations. The Green and Red bolts should not be reused.

Any of the bolts tested, when torqued to 37 ft-lbs for Black, and 59 ft-lbs for all others, will generate the needed preload on the first installation cycle without damage (7,000 to 10,000 lbs). Don’t torque the Black bolt to 59 ft-lbs, and don’t torque the other bolts to 37 ft-lbs, and you should be fine.

We believe that most LBJ bolt failures occur due to insufficient preload, which allows gapping. This subsequently allows movement between the LBJ and the knuckle, likely leading to bolt loosening and breakage. Unfortunately we don’t know the lower preload limit at which gapping can occur. Our suspicion still is that 5,000-7,000 lbs is the low safe limit (especially for offroading), based on the fact that Toyota changed the bolt design to bump the nominal preload up from 7,300 to 8,700 lbs.

If you are going to reuse the bolts, especially more than once, we would recommend doing that only with the Black, ARP, or Zinc bolts. The two flanged OEM bolts simply have too much degradation after a few cycles. You could try to compensate for the preload degradation by bumping up the installation torque level, but without a load cell you will be doing guesswork.

Torque-to-Failure Tests

In this series of tests, we will determine the torque values at which the different LBJ bolts reach their yield, ultimate, and fracture loads.

We used the same test setup as for the preload vs. torque testing - a tapped stainless steel plate to represent the steering knuckle, a flat stainless steel plate to represent the balljoint flange, and a load cell sandwiched between the two plates to measure the load. A torque transducer was used to measure the applied torque, and a digital multimeter (DMM) was used to read the load cell output. As a bolt was tightened, the display of both the DVM and the torque transducer were recorded and superimposed in the same frame, to provide a direct load vs. torque correlation.

Fracture Surfaces. (left) | Diameter reduction (Necking). (right)

When interpretating the results of the Torque-to-Failure Tests, we've added a couple of other elements to the plot to illustrate how much margin exists above the Factory Service Manual (FSM) torque value. First, a dotted green line was drawn at 59 ft-lbs (or 37 ft-lbs, as appropriate) to indicate the FSM torque value. Then, an attempt was made to identify the torque range at which the bolts yielded (this is considered to be the failure load, rather than ultimate load). Because the yield load is not as easy to pinpoint as the ultimate load, a pink box was drawn to bound the range of estimated yield load torques. These boxes should be viewed only as an approximation.

With this background out of the way, let’s get to the test results!

Toyota Green (90080-10066)

The load vs. torque traces for the two Green bolts torqued to failure show that Bolt A reached its ultimate load at 97 ft-lbs (11,666 lbs), and fractured at 108 ft-lbs (10,769 lbs), while Bolt B reached ultimate load at 85 ft-lbs (10,691 lbs), and fractured at 100 ft-lbs (9,442 lbs).

Toyota Red (90105-10505)

Similar data was plotted for the two Red bolts. Bolt A reached its ultimate load at 92.6 ft-lbs (12,564 lbs), and Bolt B at 93 ft-lbs (12,173 lbs). As for the Green bolt, the FSM torque value of 59 ft-lbs was represented by the green line, and the range of Yield Load torques was approximated by the pink box.

Toyota Black (90119-10933)

Black Bolt A reached its ultimate load at 59 ft-lbs (13,461 lbs), and Bolt B at 67.1 ft-lbs (12,095 lbs). The FSM specifies a torque of 37 ft-lbs (vs. 59 ft-lbs for all other bolts).

ARP (673-1004)

ARP 673-1004 Bolt A reached its ultimate load at 97.7 ft-lbs (14,788 lbs), and Bolt B at 104.5 ft-lbs (13,812 lbs).

Belmetric 10.9 Yellow Zinc (BF10X1.25X30YLW)

The testing started with the same 30mm bolts that were used for the load vs. torque testing. However, the torque to failure tests of these bolts were unsuccessful - some bolts stripped at the threads before reaching the Yield Load.

These bolts likely stripped because at 30mm long, they are about 2mm shorter than the Toyota OEM bolts (32mm long), leading to almost two less threads of engagement. This would not be an issue in an actual LBJ installation, but because we had a load cell sandwiched in the load path, there was not enough thread engagement to handle the higher applied loads.

So we procured some longer 35 mm Zinc bolts (BF10X1.25X35YLW) to continue the testing.

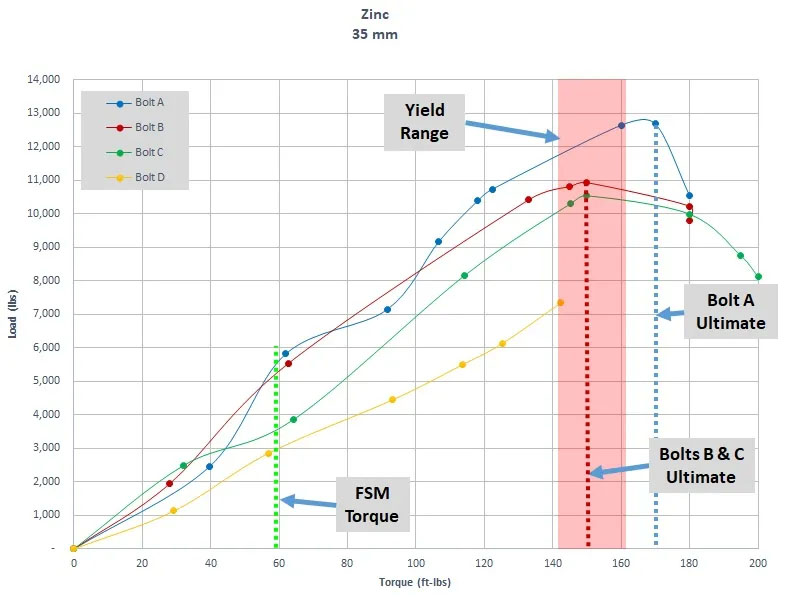

Belmetric 10.9 Yellow Zinc (BF10X1.25X35YLW)

The Zinc 35mm Bolt A reached its ultimate load at 170 ft-lbs (12,681 lbs), Bolt B at 150 ft-lbs (10,925 lbs), and Bolt C at 150 ft-lbs (10,535 lbs). The torque transducer that was used for these tests has a maximum limit of 150 ft-lbs, so above those values, we had to rely on clicking of the torque wrench. Therefore, results above 150 ft-lbs may be less accurate.

Because a significant difference in performance was noted between the 30mm and 35mm bolts, the two sets of results were combined into one plot for a closer examination.

It is evident from this plot that the preload generated at the FSM value of 59 ft-lbs was much lower for the 35mm bolts (4,500 lbs) than for the 30mm bolts (8,500 lbs). That’s only about half the preload at the same torque value!

To put this into practical terms, if we torqued a 30mm bolt to 59 ft-lbs, we could expect around 8,500 of load; but if we installed a 35mm bolt and tightened it to the same torque, we could end up with only half the load (4,500 lbs) - and we would not know this, because there would be no load cell in the setup. Also, it is notable that for some bolts, the installation torque of 59 ft-lbs is dangerously close to the yield torque of 70 ft-lbs.

There was significantly more scatter from bolt to bolt within the same batch of 35mm bolts - some bolts reached almost 6,000 lbs at 59 ft-lbs, others only 2,500 lbs. The scatter in 30mm bolts was smaller.

Finally, the 30mm bolts reached their Utimate Load at around 75 ft-lbs of torque; the 35mm needed over twice the torque (150 to 170 ft-lbs) to reach the same Ultimate load.

This tells us that the friction properties of the coating were vastly different between the 30mm and 35mm bolts. This is surprising and disconcerting, because the 35mm bolts came from the same supplier, and from the same family as the original 30 mm bolts, just 5 mm longer.

The 35mm bolts we received appeared to have different head markings than the 30mm bolts, despite being from the same family. While both heads are stamped with 10.9, the different head shape (flat vs. inset) and the different letters indicate that they likely came from different factories and different manufacturers.

Regardless of the reason, the performance of the 30mm and 35mm bolts was different enough to raise concerns. The testing clearly shows that when ordering these generic Class 10.9 zinc bolts, one would have no idea how much preload can be expected when installed to the FSM torque values - it could be as high as 10,000 lbs, or as low as 2,500 lbs. This uncertainty, and the risk of very low preload, would be highly problematic in critical installations such as LBJ.

Torque-to-Failure Takeaways

TL;DR - There is one clear loser in this testing, and that is the Zinc bolt. In general, in an application such as this, stay away from any unbranded bolt, no matter what strength class designation is marked on the bolt.

The torque to failure data is very useful in determining how close to failure the different bolts tested are when installed per the FSM requirements.

There is one clear loser in this testing, and that is the Zinc bolt. The variability from batch to batch and bolt to bolt leaves us with no idea of how much load is being introduced during torquing, and how close that load is to failure. In retrospect, this perhaps should have been expected. All the other bolts are branded (either Toyota or ARP), with specific part numbers. One would expect that for those bolts, the manufacturer has taken care to control the surface finishes and friction coefficents to serve repeatably in the expected application. In contrast, the Zinc bolts are not branded - they are supplied by a reputable supplier, but there is no control on the coatings and friction, other than to specify “Yellow Zinc” and a strength. Our test results show the danger of using these bolts without testing each batch.

Based on these tests, our recommendation would be to stay away from any unbranded bolt for the LBJ application, no matter what strength class they are.

When it comes to picking the winner, these torque to failure results are not sufficient on their own to declare one. All of the bolts (other than Zinc) reached good preload levels at FSM torque values, and had reasonable margin to failure torque. Their yield strengths were also comparable (though ARP was clearly stronger).

Winners and Losers

TL;DR - the Toyota Black Bolt w/Washer (90119-10933) is the best bolt to use, and can be used with or without the rubber dust boot. All model year 1st gen Tacoma's, 3rd gen 4Runners, and 1st gen Tundra's can use this bolt, regardless of which bolt was used when they were produced.

Taking the data collected in our previous tests, we ranked the bolts to find the winners and the losers. We first defined what we consider to be the important criteria for LBJ bolts, then assigned different weighting factors to each criteria. For example, criteria that improved confidence in knowing the actual preload generated at FSM torque was weighted more heavily than secondary criteria such as preload degradation with reuse. We then scored the bolts against these criteria using their measured performance, and added up the scores to get the total combined score for each bolt.

Using this admittedly subjective criteria, the combined scores for all bolts are in the figure above. The winners are the Black Bolt (90119-10933) and the ARP Bolt (673-1004). The Red and Green bolts were also good, but not as good the Black and ARP bolts. The 10.9 Zinc bolt was far back in last place.

Based on these results, our top recommendation for LBJ bolts would be the Toyota Black Bolt w/Washer (90119-10933) or the ARP Bolt (673-1004). The Black bolt excels in its incredibly low friction coefficient, which leads to a silk-smooth installation, and allows the bolt to reach 10,000 lb of preload at only 37 ft-lbs, significantly higher than many other bolts could achieve at 59 ft-lbs. It also provides the highest confidence in the preload generated at the applied torque, and does not have much degradation with reuse. The ARP bolt is the strongest of the group, giving it very high margin between installed torque and yield torque. It also does not degrade much with reuse.

The Red and Green bolts are certainly adequate for LBJ use, although they don’t have as much margin between installed torque and yield torque as some others. They also have the highest degradation with reuse, so we would not recommend reusing these bolts more than once. By the third or fourth installation, you would likely be seeing only half the preload at the FSM torque as you would during the first installation.

The 10.9 Zinc bolt fared far worse than all others, primarily due to its very high friction variability from unit to unit and batch to batch. Without testing each batch like we did, you would have no idea how much preload is being generated at the FSM torque. For this reason, we would recommend avoiding any generic bolts for the LBJs.

There is one caveat about the Black bolt that must be mentioned. This bolt was designed to be torqued to 37 ft-lbs, due to its very low friction coefficient. The downside of this is that if these bolts are torqued to the more commonly quoted FSM torque of 59 ft-lbs, they will likely yield. We’ve seen many forum posts where folks have torqued the Black bolts to 59 ft-lbs and had them break, then concluded (wrongly) that the Black bolts must be weaker than others. So the caveat is that if these Black bolts are installed in trucks that originally came with Red or Green bolts, anyone working on these trucks in the future must be told to torque the bolts to the lower torque values. This is particularly important if you let a mechanic work on your truck, who may not be aware that you installed non-factory bolts with lower torque requirements.

Loctite - A Remaining Concern for LBJ Bolt Failures

An important element that these tests did not address is the possibility of LBJ bolts losing preload and backing out, especially during offroad use. We believe that this is the most common failure cause for LBJ bolts, because properly preloaded bolts will rarely fail or shear off (the friction generated by four preloaded LBJ bolts is quite high, and there are two large shear cones on the LBJ that engage the steering knuckle to resist the shear loads).

However, if the bolts lose preload, they are more likely to loosen and eventually fall out. We’ve seen a number of posts with folks finding one or more missing bolts in the LBJs, suggesting that torque alone may not adequate to keep these bolts safely in place during offroad use. Even if the bolts don’t fall out, loss of preload will subject the joint to gapping and slipping, and the bolts will become more likely to fail from bending loads.

A common practice to address this risk is to use Loctite or a similar threadlocking compound. While these are effective if used properly, there are two concerns - first, there is no way to know if the Loctite was applied properly and has formed an effective bond. In addition, it is not possible to look at an installed bolt and know if Loctite was applied to it during installation. The biggest issue with Loctite is that it affects the preload that is generated during installation. While it does not change the preload very much during the first installation, our testing found that on reuse, even if the bolt threads were carefully cleaned with a wire wheel, the preload ended up being much lower than on initial installation. The most likely explanation for this is that cured Loctite remained in the female threads of the knuckle, increasing the friction coefficient. So unless the threads are chased with a tap after each use, there is likely to be much less preload in the joint than intended or desired.

Even the “best” bolts will be of no value if they loosen in use. So we believe that properly “locking” the LBJ bolts to keep them from loosening is as critical as selecting the “best” bolts, if not more so. How to achieve this effective locking is a whole separate discussion.

Detailed Scoring

Preload Uncertainty

This criteria ranks the uncertainty in preload generated by a bolt when it is torqued to FSM torque (or any other value). The narrower the range, the less uncertainty in the preload, and the higher the score.

Bolt Strength

It stands to reason that all else being equal, the stronger the bolt, the better. Stronger bolts can be preloaded to higher clamping loads, providing higher margins against slipping and gapping.

Preload at FSM Torque

Some bolts reached much higher preloads than others at FSM torque values. Higher preload is better, as it reduces the chance of gapping or slipping.

Margin between FSM torque and Yield Torque

This criteria evaluates how much safety margin exists between the FSM torque and the torque at which the bolts fail (yield). The higher the margin, the more room for error exists.

Preload Retention with Reuse

Some bolts saw a significant reduction in preload between first use and subsequent installations; others did not. Since the LBJ bolts are commonly removed to separate the knuckle from the lower control arm, the ability to reuse the bolts with high confidence would favor those bolts that perform consistently during repeated installations.

Friction Coefficient

This criteria has little practical value other than “feel”. The bolts with low friction coefficient felt very smooth during installation, and reached the FSM torque values easily. The ones with higher friction, notably the Zinc bolts, were jerky and had significant stick-slip during installation, making the torquing process more difficult.

Replace those LBJs!

Step-by-Step Replacing Lower Ball Joints (LBJ) on a 1st Gen Tacoma (or 3rd Gen 4Runner) - Over the last couple years, I've learned - mostly from others experience - that it's a good idea to keep an eye on 1st gen Tacoma lower ball joints (LBJs). If you do lots of bumpy, off-road style driving, every 30-50,000 miles is a reasonable interval to change this part of your truck, in order to prevent a catastrophic failure. So, today I headed out to the shop to check my LBJs, and here's what I found. This time, it's been 15 months, and it's definitely time for replacement. Before you do this test, you want to jack up the…

Step-by-Step Replacing Lower Ball Joints (LBJ) on a 1st Gen Tacoma (or 3rd Gen 4Runner) - Over the last couple years, I've learned - mostly from others experience - that it's a good idea to keep an eye on 1st gen Tacoma lower ball joints (LBJs). If you do lots of bumpy, off-road style driving, every 30-50,000 miles is a reasonable interval to change this part of your truck, in order to prevent a catastrophic failure. So, today I headed out to the shop to check my LBJs, and here's what I found. This time, it's been 15 months, and it's definitely time for replacement. Before you do this test, you want to jack up the… Choosing Lower Ball Joint (LBJ) Bolts - The content in this guide was originally created by Leon @SpikerEng on TacomaWorld as a series of posts over several months. I've captured it here for two reasons: I want to make sure that, should anything happen to Leon's post, that we all still have access to this amazingly useful information. As happens in forums, the information Leon posted (over time) is interspersed with a bunch of commentary from others. By consolidating it here, it becomes easier to read. Note: I've slightly edited certain bits of content in order to make the "flow" easier to consume as a single post…

Choosing Lower Ball Joint (LBJ) Bolts - The content in this guide was originally created by Leon @SpikerEng on TacomaWorld as a series of posts over several months. I've captured it here for two reasons: I want to make sure that, should anything happen to Leon's post, that we all still have access to this amazingly useful information. As happens in forums, the information Leon posted (over time) is interspersed with a bunch of commentary from others. By consolidating it here, it becomes easier to read. Note: I've slightly edited certain bits of content in order to make the "flow" easier to consume as a single post…

This is about the best darn write-up on a single part I've ever read. It leaves me pondering however, bolt selection for the two 'non-dust cover' bolts. I have a 2001 Tacoma 4WD Xtra-Cab and it uses the dust cover on the LJB's - 2 bolts w/washers & 2 bolts w/flanges per LBJ.

From what I can tell, it's appropriate to use the black 10933 on the two ears of the dust cover but two 'flange' type bolts are used on the non-dust cover holes on the LBJ. Is it because of the two different torque specs given (37 ft. lbs. on the black vs 59 ft. lbs. for the flange bolts) that you couldn't just use the black 10933 bolts all the way around? I may have missed this in the article, perhaps I should use two 10933's in the dust cover and then two of the ARP's in the non-dust cover holes. Yes?

Hey Greg,

My recommendation is to use the black bolts (w/washers) at the 37 ft-lbs torque spec all the way around. That will provide you with the most clamping force (more than you get out of the "green" or "red" flanged bolts), and more reusability in the bolts.

It used to be that folks thought that the 37 ft-lbs torque on the black bolts was "less strong" than the 59 ft-lbs on the green/red bolts, but this research proves otherwise. Rather, Toyota reformulated the bolt when they introduced the dust cover, and came out with an all-around better performing bolt. Of course, they did all this without informing any of us owners, because for the most part, why would we care? (and of course, for 99% of Tacoma owners, they were right!)

For the select few of us that do care, it's amazing that it took 25 years for someone to figure it out! ?

Just can't say thanks enough turbodb. This is unbelievably useful information especially considering as you point out, Toyota didn't seem to make this info readily available.

Your recommendation also works out well for practical reasons i.e., ordering a load of stuff right now for suspension work and it'll be much easier to just get the 8 black bolts from the same place to complete the job.

Thanks again for this excellent write-up!

Quick question , for 2001 are the black “best” bolts that goes with dust cover but what if im not installing dust cover can I still use black bolts ?

Hey Aaron, I tried to cover that in the "Bolts" section. The best bolts - regardless of dust cover usage - are the black bolts. The numbered list there, as well as the red note outlines the reasons as to why.

Hope that helps! Shout if anything is unclear, because I'd like to update it to make it clearer if it is.

Cheers ?

Great write up here. I'm not even a Tacoma owner(Highlander) and I enjoyed it. I am curious on one thing. How come the torque spec on the bolts are 37 and 59 ft/lbs vs the 92 on the Highlander?

Hey Rickey, my guess is that the lower ball joint on a Highlander is probably a different design than that of the 1st gen Tacoma (and similar model year 4Runners and Tundras). The design of the LBJ on these vehicles turned out to be an Achillies heel, and I know that Toyota redesigned them for later generations of the same vehicles. It wouldn't surprise me if the Highlander took advantage of those redesigns, and has a LBJ that is much more robust than the 4-bolt design that these trucks use, where all the tension is on the ball joint itself.

So the black bolts with the washers all around without Loctite is best?

Thanks!

Righto! That's correct. Make sure to use the proper torque values on them (they are a lower 37 ft-lbs, as compared to the flange-head bolts) and you'll be good to go 👍.