March 14-15, 2018.

There is perhaps nothing that changes the look of a truck more than adding a swing-out rear bumper. Sure, you can argue for bigger tires or lift or a front bumper, but in my mind, none of those things compare to the entirely new footprint that a rear-swing-out brings, what with the spare tire and jerry can mounts that add two additional feet to the length of your truck.

But as usual, I'm jumping into the middle of the story. Let's back up a bit.

Since starting to really build out the truck for adventuring, I've known that there were somethings that were required - sliders, skids, better suspension - just to make the truck capable of taking us to the places we wanted to go. Then, there were things that I knew were valuable - the Relentless front bumper (with Warn M8000 winch), bigger tires, and ARB air compressor - to make trips easier and safer. And then of course, there are creature comforts - things like the CVT tent, and the ARB 50qt Fridge that is a life-changer.

Naturally, a lot of these things also fall into the "cool factor" category as well. You can get a lot of mall-crawler-expo-points for this stuff, even if you never hit the trail.

But you'll be missing the best part - the adventure!

As our adventures have gotten longer and more remote, I wasn't really sure where a rear bumper fit in. Expo points and creature comfort for sure - it'd look bad-ass, and be nice to have some fold down tables in camp; but it wasn't really necessary - I mean, we've gotten along fine without it until now... And then, last November, I finally convinced myself that while it'd never really be necessary, it was something that would be valuable. Two reasons: first, it allows easier access to the spare tire (imagine trying to get the one under the bed when you're in the middle of an obstacle, on a shelf road), and even the option to carry two spares when on the trail. Second, it will give us a good place to carry more spare fuel, something that will allow us to run trips that we've not done to this point.

So, with Black Friday 2017 approaching, I made a list of requirements and researched my options (explained in a future post) and ultimately decided that a CBI Outback 1.0 with dual-swingout was the direction I was going to go. And then I patiently waited for what I hoped would be the awesomest deal ever from @CBI Offroad Fab. The deal turned out to be more meh than mind-blowing (it was ~7% off; still nothing to complain about) and I placed the order for my bumper.

And then I waited. Naturally there was some waiting because CBI had to build the bumper, but I also figured that if I picked up the bumper from CBI in Idaho Falls, I could also get a cool trip out of the situation as well. And that meant waiting for some better weather than middle-of-winter, which is when CBI let me know that the bumper was ready for pickup.

And then, opportunity knocked. Actually, Ben @m3bassman posted that he was heading to Utah for a long weekend, and asked if we could make it. Turned out we could, and the timing was perfect to head down to CBI the day before (only a few hours out of the way) to grab the bumper.

With a couple weeks to get ready, the first order of business was to remove the stock bumper and tow hitch, since I'd have nowhere to put them once I installed the new bumper (the bed would be full of our adventure gear for the trip, and I didn't want them bouncing around back there anyway, getting all scratched up).

So, I got my last look at the stock bumper and then pulled it off - a relatively easy process that involves (normally) removing the license plate lighting (which twists out, no need to unclip), unbolting 4 bolts (two on each side of the frame), and pulling off the bumper and tow receiver.

The lights and bolts came out easily enough (I've been lucky with a complete lack of seizing of any bolts so far), and the bumper slid right off. But as I'd removed the bolts, I'd noticed that when the dealer installed the tow receiver, they'd kindly welded the receiver to the frame. Not what I'd have expected, but the welds looked good, and they actually made everything easier, since I didn't need to worry about juggling removal of both the bumper and receiver at the same time.

A bit of grinding and the receiver came right off. Then, clean-up with a file and some spray paint, and the truck was looking ... different. Meaner, perhaps; definitely ready for a new rear end.

So, on the morning of March 14, we got @mini.turbodb off to school and @mrs.turbodb and I headed out across Washington, Oregon, and Idaho - intent on camping about 30 minutes from CBI, so we could show up when they opened the next morning to pick up and install the Outback 1.0 rear bumper.

As we made our way east, there were of course sights to see and conversations to be had. In Oregon, we saw a Toyota from Mexico, an unusual sighting (first ever) for us, even though we see Canadian plates all the time.

We also discussed fast food chains. See, @mrs.turbodb has always resisted Jack-in-the-Box, that is at least, officially. However, I've caught her going there on more than one occasion, and so finally got her to admit that it is - in fact - her favorite fast food. Well, she certainly wasn't happy to admit that!

We passed through Boise around 5pm and (perhaps expectedly) the Ham radio (which we'd been using to beacon on APRS) lit up with "Hey Dan - you got your ears on?" It was Ben, heading home from work - and apparently, we'd just driven right under the overpass he was on. I radioed back, but Ben was unable to hear us. Turns out it helps to have the mic actually plugged in - a problem I remedied a few minutes later at a fuel station, allowing us a quick conversation - basically just a "looking forward to meeting up tomorrow!"

With that, we headed east again, taking the scenic route up and through the snow-covered mountains as the sun set behind us. We drove into the darkness as snow stared to fall - past Craters of the Moon National Monument (which we unfortunately saw none of) and the town of Arco, Idaho - apparently the first town powered by atomic energy.

Finally, around 9:30pm we arrived in Idaho Falls. It was snowing, hard. I could tell @mrs.turbodb wasn't too happy about that - what with the plan to camp before heading to CBI, but we pushed on - it was another half an hour through the snow to our proposed camp location just east of town.

When we arrived at the Kelly Island camp site just after 10:00pm, the gate was closed (apparently it was closed each evening at 10pm) and the snow was still coming down hard. @mrs.turbodb had found another location to camp "closer to CBI" so we headed back towards town. Then, into town. And then, to the intersection of two highways - apparently, Pinecrest Golf Course - where the internet promised a free night of camping, but signs in the parking lot clearly stated, "Absolutely No Camping."

Hmm.

It was also at this time that I realized I was fighting a losing battle. See, since it'd started snowing, @mrs.turbodb had been dropping hints about, maybe, perhaps, not camping. She'd been telling me prices of the various motels in the area, and a smarter man probably would have just skipped the campground search in the first place. Defeated, we headed over to a Motel 6 and got a room.

On the plus side, it was warm, we wouldn't have to put the tent away wet in the morning, and @mrs.turbodb was happier. On the other hand, I absolutely hate parking a fully loaded truck in a Motel 6 parking lot overnight while I'm sleeping. During the night, I probably got up between 4 and 7 times during the night to look out the window and check on the truck (whenever I was awoken by a sound), but everything ended up OK and we got a nice shower out of the deal the next morning.

The next morning (March 15) we were up around 7:00am to eat a quick bowl of cereal and head over to CBI when they opened at 8:00am. It was still cold (about 30°F) but the snow had stopped and I'd we were both excited.

We headed in and took a look around as the good folks at CBI pulled the bumper out of the warehouse. I always love looking at fab shops, and CBI was a great example. Clean and well-organized, they had lots of the more commonly ordered bumpers, sliders, and other goodies ready-to-go.

When I'd arrived and mentioned that I was here to pick up my bumper, they'd asked, "Do you have a truck or trailer to carry it?" Of course, the assumption being that we'd load it in there with the forklift and take off. "Yep, I've got my truck. We came from Seattle and are headed to Utah right after this," I said, "Do you want me to install the bumper out front or along the side of the building?"

Caught a bit off-guard (I think CBI generally prefers you not install stuff in their parking lot), I got a hesitant, "Why don't you pull around the side." answer, to which I smiled and said, "Sounds great!" and within a couple minutes they brought the bumper out on a pallet, along with the swing-arms, jerry can holder, and a whole mess of hardware.

Now, I'd assumed that the bumper would have been at least partially assembled and that I'd be bolting it on to the same four bolt locations as the stock bumper, and we'd quickly be out of the CBI guys hair. But that wasn't the case, at all. The base of the Outback bumper bolted right on with a bit of help from Collin who was awesome, helping to hold it in position while I slid in the bolts and then got them tightened up. Turns out there are 6 bolts that hold on the CBI bumper - the four stock locations, and two additional for which they also provide reinforcing plates - a nice touch!

Collin seemed like he'd have stuck around and helped with the full install; unfortunately, he was quickly called back inside (again, because I think parking lot installs are generally frowned upon), but not before he had a chance to point out his own first gen, and we chatted a bit about some of the mods he wanted to do to it. Gotta say, working at CBI has to be pretty sweet that way - I sure hope he gets a good discount! 😀

Faced with a dozen parts and maybe 100 pieces of hardware on a pallet, I figured my next step should be to get some instructions. I'd tried to print some out before heading east, but as an older product (I'd guess there aren't a lot of first gen bumpers sold these days), the link on the web site was no longer working. So I headed inside.

Unfortunately, Mike couldn't find any instructions either (a bit surprising to me) but he did introduce me to Kenny. And Kenny was great. He not only came out and gave me an overview of what I needed to do to put the bumper together, but as I progressed through the install, he was happy to answer questions along the way (and in one case, even provide me with a hammer, which I'd neglected to bring with me).

I was also glad to have Kenny there as a resource for the three times that I found parts missing from my pallet! Made me extra glad I was installing the bumper at CBI, so I had easy access to those missing parts.

The first order of business was to press three bearings into each swing-arms - two in the bottom and one in the top, install the arms on the spindles, fit a grease seal over the top bearing, and finally install the top cap and keeper pins. The secrets here are to use a socket and mallet to fully seat the bearings, then a mallet and scrap of wood to seat the arms onto the spindles, and an SAE hex key to tighten the top caps.

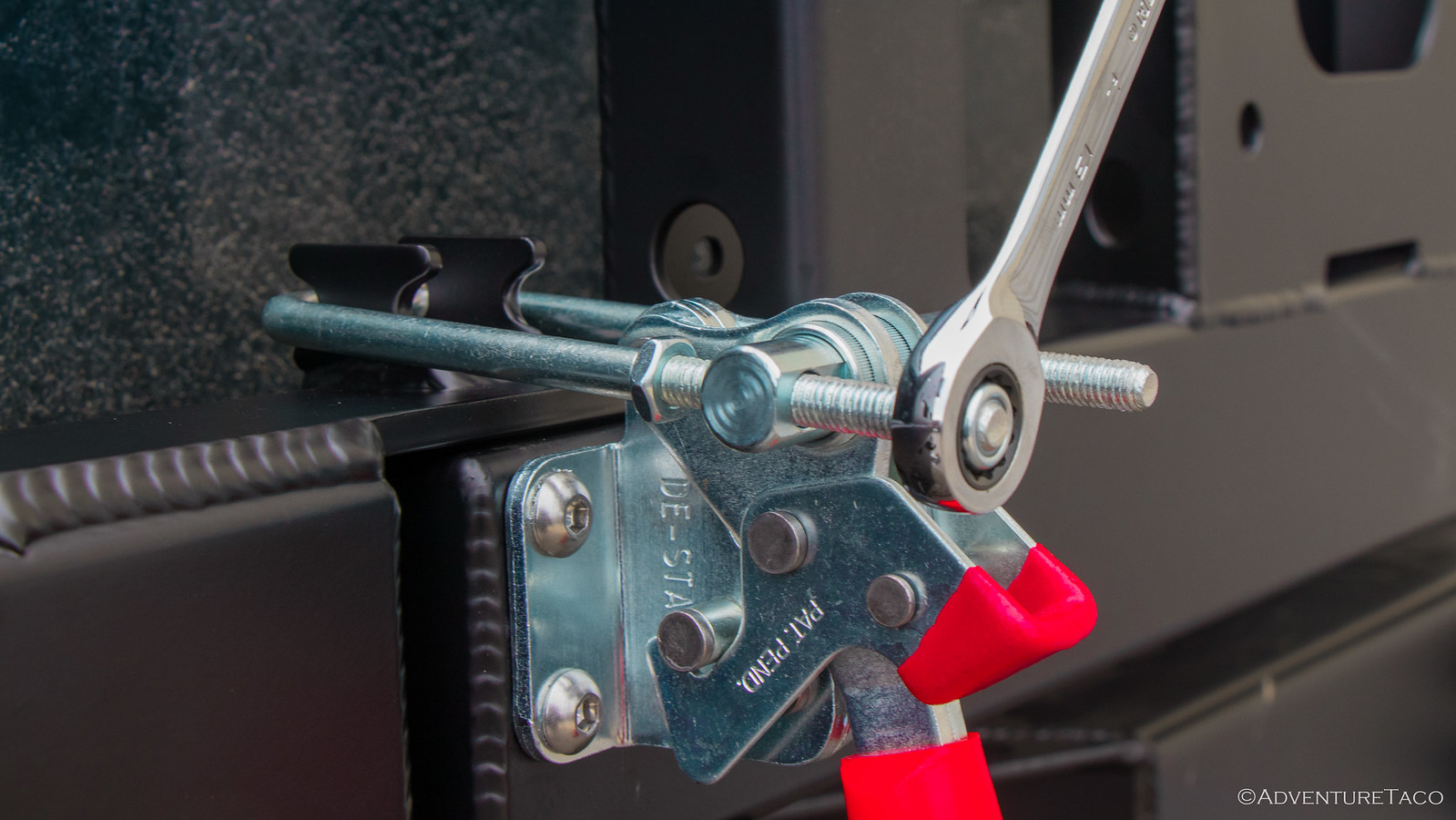

The next step was to install the latch, which secures the swing-arms, and which is itself secured with four hex head screws. The latch mechanism is pretty ingenious - it secures the two arms together, under tension - which keeps them closed without actually securing them directly to the base of the bumper. And at this point, the bumper is starting to look pretty bad-ass.

Like it should.

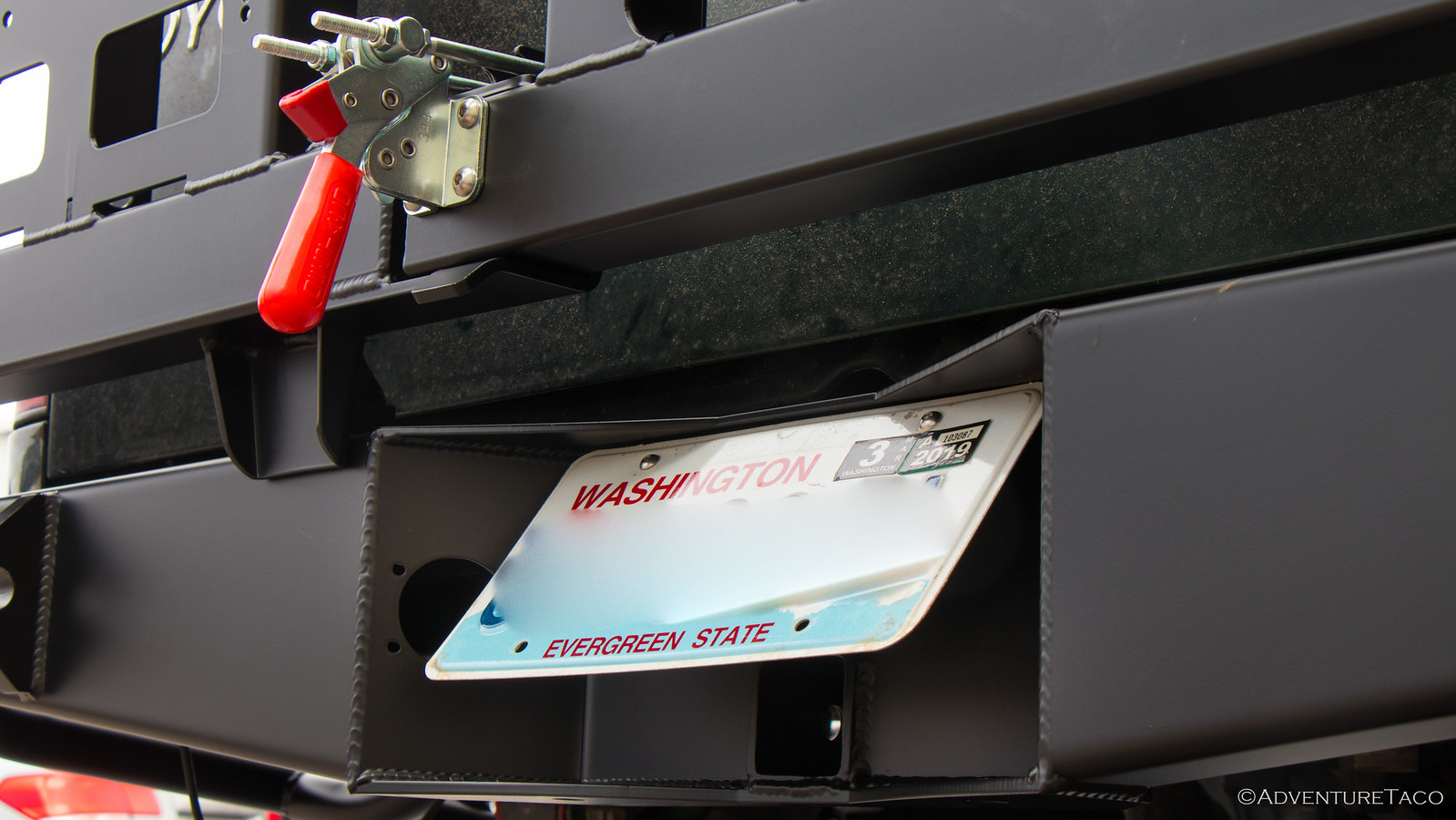

Now, it's time for the accessories - in my case, the spare tire carrier and the jerry can holder - and then finally the license plate. I started by dumping out the several pounds of hardware so I could determine where it all went, and then I got started on the tire carrier, which is secured by no fewer than 10, 7/16" grade 8 bolts. I installed this as low as I could and still have access to the latch, keeping the tire out of the wind as much as possible. The jerry can was next - four hex head screws, and finally the license plate - which hinges up to reveal the hidden hitch receiver, a very nice touch!

All that was left was to install the spare tire on the carrier, clean up after myself, head in to thank the guys at CBI for the help and understanding. While they may not have loved my local install, in the end it saved everyone time and frustration, a good thing in my book.

And yeah, the bumper looks bad-ass.

Oh, and I'm sure it'll be valuable for all those reasons I convinced myself earlier. 😉

With that, we immediately headed south to meet up with Ben and Zane (@Speedytech7) for a great adventure into The Maze District of Canyonlands National Park, but that's another story.

Re: Jack in the box... LIES ALL LIES. Though their chicken sandwich isn't all bad.

Wow, fun days!!

What is a Jerry can?

And where are the “tables” you’ll eat on??

Chicken sandwich, huh?!

But do they have good sundaes like McD’s?!

A Jerry Can holds fuel (or water, etc.). No tables on the swing-outs yet - that's something to make down the road.

When you install the table "down the road", don't forget the kitchen sink!

I saw this the other day. If only I had a source of pressurized water: Camp Table with Sink.

Very nice! I just ordered mine for my '03 this morning. Very much looking forward to bolting it all up...In about four months when I get it.