September 2, 2022.

Overall, the Tacoma has been doing great since my last rig review back in March, so I haven't felt any need to write anything about it. Still, there have been a few things worth noting on the last several trips, so let's get down to it.

- 250 Miles of Washboard - Bradshaw Trail (Mar 2022)

- Oh, So, (San Rafael) Swell (Apr 2022)

- Rock Art Overload - Nine Mile Canyon (Apr 2022)

- Owyhee Out-and-Backs (May 2022)

- A Tour of Cabins atop Steens Mountain (May 2022)

- Slowing Down in the Sierra (Jun 2022)

- Wyoming Backcountry Discovery Route (Jul 2022)

- Plumas National Forest Discovery Trail (Jul 2022)

- Lassen National Forest Discovery Trail (Jul 2022)

- Me and Mike Climb into the Kootenays (Aug 2022)

OMG, this review covers a lot of trips!

Replacing spherical bearings on the front coilover. Note that the (left) FKSSX10T-F1 bearings from the lower eye show almost no rust (since they are stainless steel) after replacement, while the (right) upper bearing FKS10T-F1 (hardened steel) shows significant rust.

TL;DR - I'm convinced that switching to extra tight stainless steel spherical bearings is the way to go, and I have numbers to prove it.

The persuader.

TL;DR - While I think that Relentless armor is some of the best out there, the mounting of the skid plates could have been better and is causing me a bit of trouble over the years (because I lightly beat the truck).

1st gen Tacoma front LCA Durobumps. The bump on the left is for the front hole of the LCA; the angled bump on the right is for the rear.

TL;DR - I've really liked all of the bump stops from Durobumps, so I've installed a second set on the front lower control arms!

Turns out, adjustment wasn't what was needed.

TL;DR - My dirver side limit strap in the front broke. I replaced it.

My original SPC UCAs with sleeved poly bushings on the left; new UCAs with the X-Axis joint on the right.

TL;DR - the last time I got an alignment, the tech mentioned that the rear passenger side bushing on the upper control arm (UCA) was starting to get a bit loose. After some consideration, I decided to install completely new UCAs, with lifetime joints so I never have to worry about those bushings again.

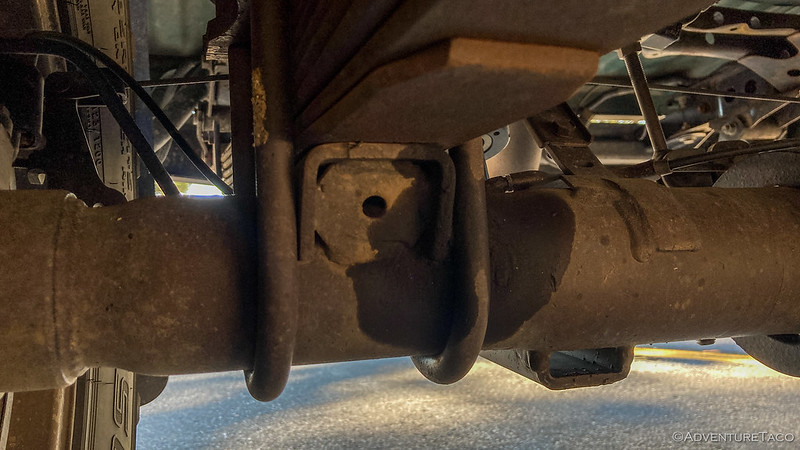

That is certainly not supposed to look like it does.

TL;DR - The passenger front corner of the bed cracked all the way down to the bed floor. I've fixed it, for now.

Out with the old, in with the new.

TL;DR - I replaced the lower ball joints (LBJs) as preventative maintenance after 75K miles.

TL;DR - The new scheel-mann seats are doing fine. The jury is still out on whether they are worth it (and will be for several years, I think.

These seats are definitely the most expensive mod I've done to the Tacoma.

Valve stems that insert from the outside!

TL;DR - My Cooper ST/Maxx tires finally gave me a bit of trouble. Still, I'll probably buy a 5th set when these wear out because they've performed better than any other tire I've seen others run on the trail.

Seemingly solved from previous Rig Reviews

Unchanged / Still an issue from previous Rig Reviews

There are some things that have been featured in Rig Reviews that are - as yet - unchanged from when I originally reviewed them. Rather than highlight those things again, I'll simply link to them here.

A lot of work there, interesting. I like that valve stem, pretty creative and I wonder why I haven't see someone making an item like that before.